Parachute cord, popularly known as “paracord,” is the undisputed king of survival cordage — it’s up there with a knife as a must-have, do-it-all prep for everything from wilderness survival to urban EDC emergencies. We spent weeks researching, buying, and intensively testing over 20 types of paracord from popular brands and outlets like REI, Home Depot, Amazon, and specialty online paracord makers, in order to find the absolute best fit for this critical prep.

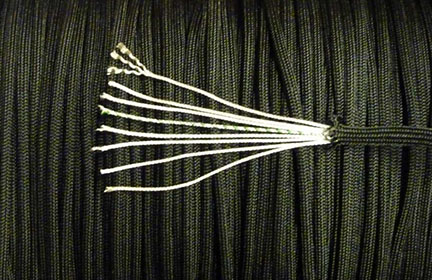

What makes paracord the Swiss Army Knife of cordage is its composite nature. It’s made up of seven or more inner strands surrounded by a woven shell, and those strands can be removed and used individually when smaller cord or thread is called for. The shell can also be unraveled if you need very fine strands.

A few of the many survival uses for paracord include:

- Building shelters by lashing together wood or random materials

- Hanging food out of bear’s reach

- Tying down loads to a truck or trailer

- Boot laces

- Creating a splint, sling, or stretcher for the injured

- Improvising a tourniquet

- Constructing traps and snares

- For hanging containers, clothing, or game out to dry or cure

- Fishing line or trotline

- Sutures

- Sewing and leather work

- Rappelling, rescue line, or climbing rope (not recommended, but you can do it in a pinch with multiple lines)

We spent over 55 hours working with the leading brands of paracord, performing static load tests, abrasion tests, and chemical tests to verify the material the cord is made from. Here is what we learned:

- The best, strongest paracord is made entirely from nylon, but polyester cord can work almost as well and is even better in some scenarios.

- Survival paracord, which has tinder and possibly other strands inside it, is awesome for crafting worn or woven items, but not ideal as your main cordage supply.

- Cords of similar composition have roughly similar performance, so there’s not a ton of difference between makers once you control for structure and materials.

- There are a lot more “milspec paracord” claims out there than there are genuine milspec paracord products. (“Milspec” is short for “military specification,” which means the product meets a set of requirements published by the US military.)

- Always burn the ends after cutting a section of paracord, because this greatly lessens the odds that the jacket will separate from the inner strands.

- More internal strands are definitely better for load bearing, and if you can afford the weight and bulk of Type IV then you should consider it.

- There is no real rule-of-thumb for how much cordage you should have in an emergency situation. Our research indicates that most preppers carry between 50 and 100 feet in a Get Home Bag or EDC bag, and keep a few hundred feet in a roll at home.

- Sunlight is the enemy of milspec nylon paracord, and it should be kept out of direct sun if possible.

- Soaking wet paracord is slightly weaker than dry paracord, so try to let it dry out before loading it.

- Both nylon and polyester, the two most popular paracord materials, don’t absorb much water, resist mildew and mold, and dry relatively quickly, so moisture isn’t much of a threat to good paracord.

- There are high-tech cords, mostly used for winches, with vastly superior strength/weight ratios on the market, but because of its composite structure, low cost, and versatility, paracord is still the cordage choice of most preppers.

- When using paracord in an application where it will rub up against an object and fray, there are a number of key factors that make a huge difference in how well it holds up — e.g. load at the anchor point, surface texture of the object it’s lashed to, speed at which the cord rubs the object, etc. Subtle changes spell huge differences in durability.

Full details on how we pick the best paracord for emergencies, wilderness survival, general home cordage supplies, and more below the fold.

5col 550 Type 3 Nylon Parachute Paracord

The best paracord for preppers is the milspec 5col 550 Type III MIL-C-5040H Nylon Parachute Paracord. This reasonably priced paracord did well in our load tests, and was a standout in our abrasion tests. It has a good texture and solid structure that makes it easy to work with. Most importantly, the 5col is the only paracord in this roundup that we’re extremely confident is genuine milspec from a US government certified manufacturer as claimed — 5col advertises that this cord is certified for use in parachute lines, and offers a certificate of conformance from the manufacturer on request. In a market awash in false claims and bait-and-switch products, this is the definitely the real deal, and it will be our benchmark cordage in future versions of this review.

If you afford the increased cost and bulk of upgrading to Type IV paracord, with eleven internal strands (vs. Type III’s seven strands) and greater load-bearing capacity, then we recommend the 5col Type IV. Note that we did not test this particular flavor of Type IV — we tested the ToughGrid Type IV, which is excellent but is from a different maker and we’re not as confident in the milspec claim. Still, the 5col Type IV is from the same maker and should be identical in materials and quality to the 5col Type III.

ParacordGalaxy 550 Paracord

The best budget paracord is the Paracord Galaxy Commercial 550, which at $0.05 per foot is an incredible value, especially for its excellent load-bearing ability. If you want to stock up on hundreds of feet of bulk, all-nylon paracord for crafts and general home supplies, this is the best deal going. Even if you add another $6 for shipping, this stuff still wins by a wide margin.

UST ParaTinder

So-called “survival” paracord has extra strands woven into it — usually tinder, but sometimes fishing line or other specialty wire — and while we don’t recommend it as your main cordage prep (more on this, below), we definitely love it for bracelets and lanyards. The best survival paracord is the all-nylon, ultra-tough UST Paratinder. The internal waxed jute strand is generously sized and easy to light with a firesteel, and the cord itself did great in our static load testing. The Paratinder also dominated our abrasion testing — while we had some issues with the abrasion test setup and are not publishing specific results from it, we can say that the Paratinder was an absolute beast and stood up to more abuse than anything else we tested.

Titan SurvivorCord

If you can afford the extra cost, the Titan SurvivorCord 100 feet is an awesome survival cord upgrade. This hybrid nylon/polyester cord features a waxed jute strand, mono fishing line, and conductive metal wire for traps or whatever else you can dream up. Titan SurvivorCord’s internal polyester construction* (the shell is nylon) makes it lighter and less stretchy than our main survival pick, so it’s ideal for some woven items like rifle slings, straps, and belts. You can also get this cordage in more color and length options than the Paratinder, making it easier to match to packs and handles when used for zipper pulls or lanyards.

*Note: Titan SurvivorCord is advertised as all-nylon, but our tests revealed the internal strands to be polyester. We were pretty bummed to find out that this cord currently isn’t what it’s sold as, because it was and still is one of the best cords we tested. We’re still recommending it, though, despite polyester construction. For more on this issue and how Titan is resolving it, see the “Titan Survival” section in the last section of this review.

GearAid 550 Reflective

Everbilt Paracord Rope

Reflective paracord is increasingly popular with outdoor enthusiasts, and for good reason. Whether you’re trying to avoid tripping over tent guylines in the dark, or you’re searching for a paracord-wrapped knife you dropped at dusk, reflective paracord can save you a lot of grief.

The very best reflective paracord for preppers is the Gear Aid paracord that’s widely available on the rack at REI. This is the only commercial paracord we tested that had the same structure as milspec, and it’s extremely tough and a great value at roughly $0.13 per foot. This really rocked our load tests, and we’d use it with total confidence in a survival situation.

The best bulk paracord-like rope is the Everbilt “Paracord” from Home Depot. Though it has “paracord” in the name, it’s not paracord in terms of structure, so it can’t be disassembled and used in parts — but it’s still amazingly tough and ultra-cheap. In terms of load-bearing ability per dollar, this is the best cordage in this guide for things like truck tie-downs or shelter building. And its polyester construction makes it more UV resistant than regular paracord, which means it’ll stay strong after extensive sun exposure.

Be prepared. Don’t be a victim.

Want more great content and giveaways? Sign up for The Prepared’s free newsletter and get the best prepping content straight to your inbox. 1-2 emails a month, 0% spam.

Paracord 101

Paracord is a kind of kernmantle rope originally intended for use as suspension line in US military parachutes, so there is a military specification document that describes six different types of paracord with different attributes and strength ratings.

In this review, we mainly concern ourselves with Type III paracord, which is rated for 550 pounds and is often called “550 paracord.” The 550 cord is by far the most popular type for everyone from hobbyists to survivalists, and it’s available on the market in the following flavors:

- Milspec: This is paracord that’s manufactured in accordance with the MIL-C-5040H standard, preferably by a certified government contractor.

- Commercial: Sometimes the same as milspec, but without the special colored identification strand required by the spec. Other times, it’s mystery meat cord.

- Craft: A subtype of commercial paracord intended for decorative and lightweight uses, like bracelets and art projects. This is most often cheap polyester cord (contrast to real milspec, which is always nylon).

- Fake milspec: There are a few brands that advertise “milspec” paracord, but it’s not really milspec because it doesn’t meet one requirement or other. Sometimes it’s hard to tell without close inspection or chemical testing whether a particular cord is real milspec or fake.

- Survival: This is commercial paracord with extra strands in it for lighting fires, catching fish, setting snares, and so on.

In this review, we also looked at a few non-550 options that seemed suitable for survival use, like the paracord-style kermantel rope sold as Everbuilt “paracord” at Home Depot, PMI utility cord from REI, and some quality Type IV milspec paracord just for the sake of comparison.

A standard piece of 550 paracord consists of from 7 to 9 strands, wrapped in a woven shell. The individual strands themselves consist of two or three yarns all twisted together to make the yarn. For legitimate milspec paracord, there must be three yarns per strand, while much commercial cord will have only two yarns per strand.

Throughout this guide, we’ll refer to “7/3” construction as a shorthand way of saying, “7 strands, 3 yarns per strand.” Similarly, 7/2 would mean 7 strands and 2 yarns per strand.

Real milspec paracord contains one colored marker strand that identifies the government certified manufacturer. Each marker strand is supposed to be unique to a manufacturer, so two milspec paracord samples with the same marker strand should be from the same maker, no matter how they’re branded and resold. But some makers put a fake marker strand in there, so you can’t really rely on this. Nonetheless, without the marker strand, it’s definitely not milspec.

Milspec cord is made entirely of nylon because it’s important that the cord be able to stretch to support the dynamic load of a human body suspended from parachute lines. The military also likes nylon’s amazing abrasion resistance, oil resistance, and quick drying nature.

Good commercial paracord should be identical to milspec — including the all-nylon construction — but without the marker strand. However, almost all the commercial cord in this roundup is of a 7 threads / 2 yarns construction, and not the required 7/3. This is done to save money and weight. Some commercial paracord will save money and weight by using polyester for either the jacket or the internal strands

Most craft paracord is all-polyester and is openly advertised as such. It may or may not have three yarns per strand, but it almost always has at least seven strands in it. If it’s polyester with 7/2 construction, then it’s likely to be very weak. Given how cheap some of the all-nylon 7/2 paracord is, there’s not much reason to buy the polyester stuff.

If you cut open your paracord and you can’t make out individual strands and yarns, then what you have is just kernmantle rope — this is true even if it says “paracord” on the package, as is the case with the Everbuilt cord at Home Depot.

Regular kernmantle rope can be really great to have in an emergency, and the Home Depot cord we tested is incredibly tough and inexpensive. As long as you know what you’re getting and you understand its limitations (i.e. you can’t easily disassemble it into smaller threads for other uses), it can be a solid, cheap prep.

The image above shows three survival paracord products with the extra strands visible. In our testing, we found that these strands don’t necessarily seem to add much load-bearing capacity, but we can definitely see how they’d be useful in a survival situation.

Paracord materials

Most Paracord is made from one of two main materials: nylon or polyester.

While nylon is widely considered to be the only “real paracord” material, both materials have different strengths and weaknesses that make them good for different applications.

| Nylon | Polyester | |

|---|---|---|

| Abrasion resistance | Best | Good |

| Moisture absorption | Low | Lowest |

| Quick drying | Best | Good |

| Oil resistant | Yes | No |

| Weight | Low | Lowest |

| Stretch | High | Low |

You can tell what kind of material your cord is made of with a simple burn test. The video below compares a polyester craft paracord strand from a PSKOOK with a nylon strand from the UST Paratinder. The strand at the tip of the pliers giving off black smoke is the polyester one.

Polyester has some advantages over nylon, like lighter weight and better UV resistance.

Don’t discount UV resistance as a polyester advantage, because one study shows that polyester can withstand a year of direct sun exposure and still keep 67 percent of its strength. We don’t have comparable numbers for nylon, but we’ve read that nylon is significantly less UV resistant than polyester, so for applications with direct sun exposure polyester wins.

Polyester also doesn’t stretch like nylon, and you may not want nylon’s stretchiness for whatever reason — maybe you’re suspending a load at a particular height as part of a trap and you don’t want it to drop a bit. Or maybe it’s for a rifle sling and you really don’t want any give to it. In these cases, polyester wins.

Choosing the right cordage

It may seem obvious that preppers should buy paracord to fill every possible cordage application they might encounter in an emergency, which means just buying the best paracord based on price and performance. But the diversity in the paracord market — especially the availability of paracord with specialty strands like flax or jute — means that if you’re willing to specialize a bit, you can do better than just using plain paracord for every application.

Milspec paracord and quality commercial paracord

Preppers who can afford it will want to stock up on a few hundred feet of quality milspec Type III or Type IV (or a commercial near equivalent), to form the basis of this part of their preps. This the original survival cordage loved by preppers and soldiers for generations and will serve you well in a wide array of applications.

Lightweight and strong, Type III milspec cord is great for all types of lashing, weaving, and hanging, and is also the right kind of paracord to get if you think you might be heavily loading it with something (i.e. a hammock or stretcher).

Type IV milspec paracord has eleven strands and should be rated to handle up to 750 pounds of load.

Because of the extra internal strands and 11/3 construction, Type IV is slightly bulkier than the seven-strand Type III. This extra bulk is something to consider if you’re putting a hank of cordage in a Bug Out Bag. So you might consider regular Type III in an EDC briefcase or BoB, and Type IV for heavy-duty home use.

Craft paracord

If you’re just using the cord for boot laces, pack lashings, or other relatively low-load applications, there’s no reason to suffer the extra cost and bulk of milspec paracord. Some of the 7/2 all-nylon cord we tested is quite good and will be good enough for the majority of applications in an emergency scenario.

If our budget craft paracord pick makes up the bulk of your emergency cordage supplies, you’re almost certainly going to be fine. So don’t ignore the craft paracord market, especially if you’re using it to make woven products like bracelets and lanyards that are just intended to be spare, light-use emergency cordage.

Survival paracord

None of the survival paracord that we got our hands on is real milspec paracord or even high-quality commercial grade cord — it’s just a turbocharged flavor of craft paracord, and should be used as such.

It’s important to know that you can’t easily extract the specialty strands without taking apart the entire length of cord. And the more of a particular type of strand you’re trying to tease out, the harder that is to do without just disassembling the whole cord. So if you need 20 feet of wire for a snare, then you’ll probably need to undo 20 feet of cord. If that’s 20 feet from a bracelet or weapon sling, that’s not so bad. But if you just unraveled 20 feet of a 50-foot main cordage supply, you may be in trouble.

Because you may have to disassemble your paracord to get at the specialty strands, survival paracord is not ideal as your main prepper cordage supply. Instead, consider it for lightweight applications where you’re using it lengths of a few feet at a time, e.g. lanyards, belts, bracelets, rifle slings, tent ties, zipper pulls, and other secondary roles where it can serve as a backup source of tinder, thread, or fishing line.

Finally, just because you’re hiding these extra strands inside a length of paracord doesn’t make them magically add zero to your pack weight. You’re still carrying a bunch of fishing line, tinder, and whatever else, just in a very inconvenient form that’s hard to get at when you need it. So it’s far better to pack line, thread, wire, and other specialized cordage in separate, more accessible rolls than it is to tangle all that material up inside your main cordage supply, where it can be impossible to extract without totally disassembling the cord.

Starting a fire with survival paracord

The waxed jute tinder strands in survival paracord kick right off with a ferro rod… if you know what you’re doing. Unfortunately, many people don’t know what they’re doing, so it’s easy to find complaints and even videos to the effect that these waxed jute strands are “impossible” to light with a ferro rod. Here’s one example, but there are many more out there:

If you actually know how to use a ferro rod, then you know that the guy in the video clearly does not. Here is me lighting a strand of UST Paratinder with a ferro rod. It’s not rocket science — notice the difference in technique:

The bigger jute strands in the UST Paratinder and the PSKOOK cords are better than the smaller strands in the Titan and Paracord Planet cords. We prefer the waxed tinder to the unwaxed (as in the Paracord Planet tinder). The paraffin wax adds some water resistance — if the cord gets soaked you can more easily wipe it down and get it dry. And it also adds some burn time, making the flame more candle-like and wind-resistant.

In fact, if you leave a waxed jute cord intact and light it with a match or lighter, it burns slowly like a candle and makes a great fire starting aid.

The unwaxed strand in the Paracord Planet tinder frays more easily and is easier to get started with a steel, but it burns faster and doesn’t have the added moisture resistance of waxed line, which is why we didn’t pick it.

Static load testing

Paracord is rated by its ability to handle a static load, so our first and primary test was designed to test that rating.

Summary: There were meaningful differences in the static load-bearing capabilities of the different cords, and these differences had no apparent correlation to cost per foot. Some cheap cords were super tough, and some expensive cords were relatively weak.

Most of the cords broke somewhere inside the bowline knot we tied, which was exactly what we expected. Any place where there are bends in the cord will be stress points that are prone to breakage, so knots will be the most likely point of failure in any realistic cord use.

How we tested static load

We hung a crane load tester from a metal scaffold and used a “come-along” winch on the bottom to steadily increase the load until the cord broke.

We tied bowline knots at each end of the cord and then shackled the bowline loops to the testing harness. (There was a span of about 20 hours between when we tied all the bowline loops and when we load tested the cord, so all the knots had time to set and have whatever impact on load strength.)

We selected the bowline because it’s a very easy knot that many preppers will know and naturally use, and in fact, it’s the one knot we recommend you learn if you’re going to learn only one. The bowline works well enough in break strength tests that it’s a middle-of-the-road choice. We wanted the tests to be realistic, so we didn’t want to use a specialty climbing knot.

With the rope installed in the test rig, we then steadily tightened the winch, filming the crane scale with an iPhone so that we could capture the exact readout when the cord broke.

We tested two samples of each rope and averaged the results. We didn’t see much variation from sample to sample, and the tests were quite consistent from run to run with the same cord, so we feel really good about these numbers.

Wet load test

We selected some representative samples of cord that appeared to be of similar make, tied them with a bowline at each end, and soaked them in water for 20 hours. We then load tested them the same way we did the regular static load tests.

We found that the soaked paracord held roughly 15 to 20 percent less weight than the dry cord, for both polyester and nylon variants. Both polyester and nylon absorb water, and given that we tied the loops on the ends of the cords before soaking them, our guess is that the water quickly swelled the material and put the knots under increased strain for most of the soak time — hence we saw a roughly 20% loss of load-bearing strength at the knot for the soaked cords.

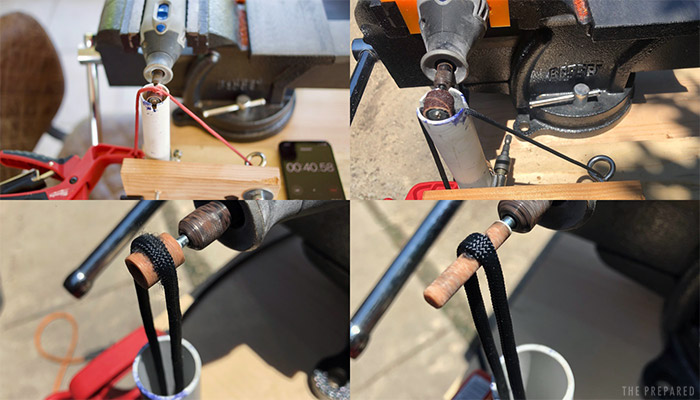

Abrasion testing

We spent over three days designing, redesigning, and tweaking different iterations of an abrasion testing setup, and we ultimately could not come up with a test that gave reliable, consistent results. We’re preppers just like you, and we plan to rely on the results of this testing in our own preps, so we’re not interested in faking or fudging any numbers just for the sake of having some results — we couldn’t make this work to our satisfaction, so we had to ditch it.

Despite the fact that we don’t have a results column to show you for this test, we did learn a ton about how cordage abrades and ruptures over the course of trying and failing at this. This information should be useful for preppers who plan to use cordage in an emergency.

Summary: The ability of any given type of paracord to withstand abrasion without splitting in two is very highly dependent on subtle changes in the following conditions:

- The texture of the object the cord is rubbing against

- The speed of the rubbing

- The tension on the cord

- The distribution of tension on the cord (i.e. is the weight up near the point of abrasion, or is it hanging much lower, with the tension distributed across more cordage.)

Even the smallest changes in any of the above factors have a far larger impact on a cord’s ability to withstand abrasion than the makeup of the cord itself, at least for the different cords in our test batch. Another way of putting this is if you take any care to buy quality paracord (i.e. not craft paracord, but cord intended for survival use), then the conditions where you’re using the cord will be the overwhelming factor in how it holds up.

So if you’re using cordage in a situation where it will abrade, it’s important to be aware of the factors above and to do anything you can to tip the odds in your favor. Per our testing, even the smallest bit of friction reduction or tension reduction at the anchor point will have an outsized impact on the cord’s durability, so don’t shy away from making small tweaks that might help.

How we tested abrasion

All of the test setups involved the same basic mode of operation: a two- or five-pound load (we tried both in different setups), pushed against a rotating drill or Dremel bit to create friction that would abrade the cord until it split and the load dropped. We used a chronograph to measure the time from the start of the bit’s rotating to the time the cord ruptured completely and the weight dropped.

In some setups, the cord was draped over the bit, and in others, it was suspended under it with the bit pressing down on it. Sometimes we used different grits of grinding bits and in others all-metal spade bits. We tried different loads at different heights.

Here’s what we learned in hundreds of test runs:

The amount of load on the cord has a massive impact on the speed of abrasion. This may seem intuitively obvious, but our testing revealed that all the cord types are incredibly sensitive to even the subtlest changes in tension. For instance, the difference between a free hanging cord with a two-pound load and that same setup where the cord is angled slightly over the corner of a piece of wood is a 2X or 3X increase in rupture time.

Subtle changes in grit matter a lot. Some of the grinding bits we used would wear down over the course of ten or so runs, and if we went back and tested against a baseline cord that we started with, we’d find that the rupture time had increased by 50% or more.

For the sturdier drill and Dremel bits that didn’t wear down, these still suffered changes in friction coefficient as material from the test runs was deposited in their grit. To really make these work, we’d need to thoroughly clean the bit with a brush and solution after every single run, and then dry it.

The rotating speed of the bit is very important, and we saw with some cordless drill tests that as the battery wound down just a very small amount, the rupture times would start to stretch out considerably. In fact, even in the case of Dremel and drills with cords, these are not precision instruments and aren’t designed to hold a specific rotational velocity under different friction and load variations, so depending on the amount of heat built up in the motor and other factors peculiar to the test rig (e.g. friction on a support part holding up the bit) they might slow down enough on a particular run to have a noticeable impact on the results.

With the tools and the time constraints we were working with, it was impossible to control all of the above variables to the degree that they’d need to be controlled in order to give reasonably accurate results. We just didn’t feel we could rely on any of our test setups to provide an accurate baseline for comparing all the brands of cord we bought and tested.

And as sensitive as the cordage these factors, it’s likely that a cord that would perform well in one type of controlled test might underperform with a different test setup. So even if we had come up with the ideal test rig and controlled all the variables, we wouldn’t have confidence that the results reflect what you’d find in the field.

Dynamic load testing

We spent some time working on a dynamic load test, but ultimately we were thwarted by our equipment and by some the same variability issues described for the abrasion testing.

To test dynamic load, we’d need a dynamometer that can not only record very brief, transient spikes in load up to 1,000 pounds or more, but that can capture the peak load at the moment of cord failure and keep it on the readout. None of this was something we could accomplish with our crane scale, so we tried a few drop tests with kettlebells of different weights hitched to them.

Full review notes of the top contenders

Some of these cords seem to be rebranded from the same maker. They have the same marker strand, materials, and construction, similar performance, and close visual inspection under a magnifying glass suggest they’re identical.

We have no way of knowing the names of the makers, so we’ve assigned them letters and grouped together with the brands that seem to belong to them, below.

Maker A

Tough Grid Paracord, Type IV: This was my favorite milspec paracord of the whole roundup, and it’s what I’d buy. It has a separate marker strand, the right materials, and beat the rest of the pack on the static load test. Of course, this latter win was to be expected, because it has more strands than the Type III. It is bulkier than the same length of Type III, but you get more material to work with.

The marker strand is one of the 11 strands advertised, but it’s too thin to be a real load-bearing strand, so this is better thought of as a 10-strand product

My favorite thing about this cord is the texture. All of the cord from this maker has a kind of cloth-like texture to the outer shell that feels grippy and natural, which makes it easy and pleasant to work with. It holds a knot well, and generally feels like high-quality cordage.

GOLBERG Mil-C-5040H Mil-Spec: Same in every respect as the ToughGrid Type IV, except in a 7/3 format. Same texture and feel, and good performance. This is milspec nylon/nylon cord with 7/3 construction and a separate marker strand.

ParacordPlanet.com 550 (military grade): Seems identical to the Goldberg — very tough, and has a great feel and good build quality. It’s relatively expensive, though. You definitely can’t go wrong with it, especially if you get it on sale. But watch out, because this vendor also sells commercial grade paracord that’s a little cheaper, so if you want their military-grade cord you need double check what you’re buying.

Maker B

The Paracord Store 550: Good quality milspec cord, claims to be from a certified US government supplier. The ID strand is one of the 7 load-bearing strands, and it has 7/3, nylon/nylon construction. Holds a lot of weight, and has an average feel, texture, and appearance. Very comparable to the ParacordPlanet.com cord, and possibly cheaper depending on shipping. Claims to be made in the USA.

SGT KNOTS: Good all-nylon 7/3 paracord at a great price. Same marker strand as The Paracord Store’s milspec 550 and seems in all respects identical to it, so they’re probably from the same maker. They certainly feel and look the exact same, perform similarly, and are priced identically.

Vigilant Gear 550: Same marker strand as Sgt Knots and The Paracord Store, and same materials, construction, and feel. Similar performance, as well.

Tactical 365 MIL-C-5040H: Close visual inspection and burn testing suggests that this cordage is the exact same as the other milspec 550 that seems to be from this maker, but it noticeably underperformed in our load test and we’re not sure why. We tested this cordage six times and got readings from 300 to 351 pounds — even the high end there is over 30 pounds away from the lowest reading we got out of any other flavor of MIL-C-5040H.

It’s tough to know what’s going on here, but it could be a non-certified maker using a lower grade of nylon and trying to pass it off as the work of a certified maker using a cloned colored marker strand. Or, the cord could’ve been left in the sun and weakened from UV exposure, or we got a bad batch. It’s hard to say.

Maker C

5col 550 Type 3 Nylon Parachute Paracord: This all-nylon cord has 8/3 construction, with a load-bearing ID marker as one of the 8 strands. It claims to be US made and Berry Amendment compliant and is quite tough. It’s not the cheapest, but it’s good cord, and it’s probably the best value on milspec 550 available on Amazon.

Titan Survival

This maker’s cordage is advertised as milspec and all-nylon. Unfortunately, both a burn test and a followup muriatic acid test revealed that the inner strands of this cordage are polyester, and not nylon as advertised.

We contacted Titan, and after a lengthy email exchange and their own internal investigation, it does appear that they were deceived by one of their suppliers. The president tells us they’re fixing their internal QA process so that this doesn’t happen again, and will soon begin shipping confirmed all-nylon cordage into the channel.

They claim they don’t know how much of the polyester cord is currently in retail channels, but it typically takes about two months for all the channel inventory to turn over. So if you want the nylon version of any of their cordage, it’s best to wait at least two months before buying any.

We’ll also be doing a followup purchase in two months, with some testing to confirm that they’ve switched back to nylon as promised.

Titan SurvivorCord: This is a really great concept, and was my favorite specialty cord of the roundup. It outperformed on the load tests, and the extra lines — fishing line, waxed jute tinder, and copper wire — all add a ton of value.

It has a very good texture and feel really nice visual aesthetics, and is attractively packaged. If this stuff was nylon, it would be an absolute beast.

The tinder strand in this cord is paraffin waxed jute and is fairly thin.

Titan WarriorCord: Similar to the Survivor Cord, but without the added specialty strands. When they do fix their supply issue and we can get a nylon version of this stuff, we hope that it performs well enough to match the expensive $0.20/foot price.

PSKOOK

This Chinese maker’s survival paracord competes with Titan Survival Cord, in that it includes the following specialty strands: cotton, waxed flax, 40lb test fishing line. As polyester cord, it’s quite solid and very reasonably priced. So if you’re looking for what is basically craft paracord with specialty survival strands, perhaps as a budget survival cord option, then this is a decent choice.

Be careful, though, because this same cordage is being resold on Amazon as “Power Paracord,” and whoever’s behind “Power Paracord” is advertising it as milspec (i.e. nylon) when it definitely is not. Buying from “Power Paracord” gets you the branded PSKOOK cord, and PSKOOK themselves openly admit that this is polyester cord.