-

Best Replies

Robert LarsonContributor Robert Larson - November 6, 2020

I wanted to share my first experience of making soap. My goal was to create the cheapest unscented soap as I could. Maybe it would save me some money, I would learn a new prepping/self sufficiency skill, and I would have a stockpile of soap! I thought that getting waste fat from the butcher was going to be a free solution for my fat/oil because when I went there before, they said that they just throw the cut off fat away and they could save me up as much as I wanted. But the next time I went, they enacted a new rule and would have to charge me for it. So I decided on the next cheapest option, getting two huge jugs of canola oil from Costco.

Here is what I wrote down 8 months ago, pardon the poor grammar, I just quickly took down these notes so I would remember what I did.

On 3/16/2020 I made my first batch of soap. I used 95% Canola oil and 5% Castor oil. Using Soapcalc.net, it calculated what I needed to use.

-I used a large Pyrex measuring cup to measure out 475g of canola oil.

-In a disposable plastic cup I measured out 25g of castor oil.

-In another large Pyrex measuring cup I measured out 190g of distilled water.

-In another disposable plastic cup I measured out 62g of Lye.

I put on safety goggles, gloves, and long sleeve shirt, and pants then went outside (very important!) I put the water in one 3 gallon bucket. ALWAYS PUT THE WATER IN FIRST! Then I poured in the lye. I used a bamboo kebab skewer to stir the lye until it was clear. The water and lye mixture gave off some really nasty fumes and the water rose to around 130 degrees.

Back inside, I took the Pyrex of canola oil and put it in the microwave for 2 minutes to bring it up to 130 degrees to match the same temperature as the lye water. I then poured both kinds of oil in the other 3 gallon gray bucket. I then poured the lye mixture into the oil mixture and used an electric mixer to mix for probably 2-3 minutes until it was very creamy looking and 100% mixed.

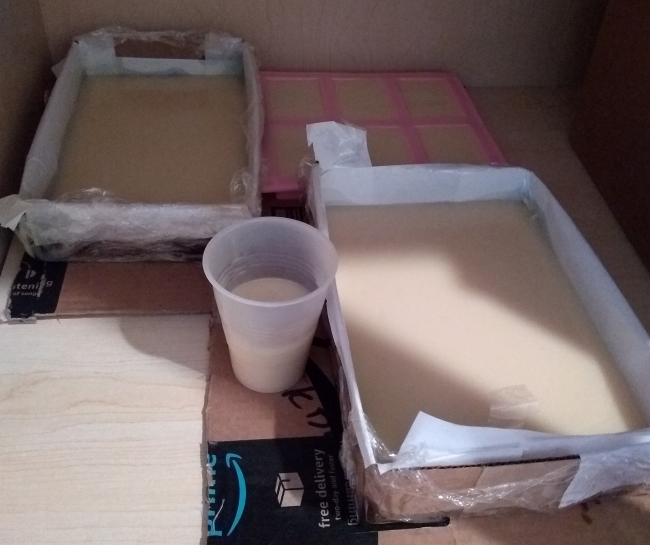

I then poured the mixture it into some molds.

The above batch filled up the pink silicone mold and it had enough left for ½ of a disposable plastic cup.

I wanted to make another batch so I doubled the above recipe. This was able to fill both of the cardboard molds.

This probably was a mistake to use a DIY cardboard mold. I first made the cardboard boxes and lined them with freezer paper. When I poured in the soap mix it started to seep through the cracks of the freezer paper and through the cardboard onto the table. I hurried and covered the outside of the cardboard molds with plastic wrap and that seemed to hold it. If I am going to use a cardboard mold again, I will wrap the entire thing in plastic wrap before I then line the inside with freezer paper.

I left the soap molds in a dark cool cupboard covered with a cloth for over 3 weeks until they were solid enough to be cut. I cut them into pieces and stood them up to get as much airflow as possible. I then left them in a cupboard for 7 months to cure.

7 months later, can you guess how they turned out!?

HORRIBLE…

DO NOT USE CANOLA OIL! It is not a good smelling oil, and I couldn’t get over the smell. It just was not worth it. The first two lathers of the soap worked well, but then the soap gave off a slimy gooey feeling after that – yuck!

I do have a couple jars of beef and pork lard that I got for free this year. Lard is the original way to made soap and how people have been doing it for hundreds of years, so hopefully it will work this time.

I’ll report back when I make that lard soap.

-

Comments (22)

-

Supersonic - May 14, 2020

I’ve read that you can make it pretty easily with bacon fat but I’ve also heard that it’s not easy at all. Go figure. Check reddit r/soapmaking if you’re genuinely going to give it a shot. I think it’s a cool project, but I’m content to just stock up on it. It was hard to find back in March, but I see plenty in stores right now.

-

Josh CentersContributor - May 14, 2020

My wife is considering it, and I’ve researched it in the past. You’ll definitely want to invest in goggles to protect your eyes when handling lye.

-

Roland - May 15, 2020

Get a copy of the Encyclopedia of Country Living. It’s pretty well known and goes over soap. There’s a ton of stuff in there also in case you get the bug and want to make more of your own preps. Good jumping off point.

-

Scott Byron - June 4, 2020

I once melted together all my scraps of soap and cooled them down. The final result was a soap a little bit on the mushy side, so that wasn’t great. But it made me feel good that I used thos finals craps that otherwise would have been trashed.

-

Zabeth - June 21, 2020

Yes, I have made cold process soap with lye and a combination of palm, coconut, and olive oils with a few drops of lemon essential oil added at trace to give it a light, fresh scent. It turned out well, and I enjoyed using it.

Zabeth

-

Friend of the Pod - June 23, 2020

I have made soap from scratch many times. It’s not difficult, and home made soap is as good or better than what you can buy at the store, assuming you’re using a decent recipe. Is it worthwhile? Only if you enjoy making stuff yourself, which I do. Or if, like me, most commercial soaps make you itch, and the ones that don’t (e.g. Kirk’s Coco Castille) cost vastly more than what it would cost to make something equivalent yourself.

-

Robert LarsonContributor - November 6, 2020

I wanted to share my first experience of making soap. My goal was to create the cheapest unscented soap as I could. Maybe it would save me some money, I would learn a new prepping/self sufficiency skill, and I would have a stockpile of soap! I thought that getting waste fat from the butcher was going to be a free solution for my fat/oil because when I went there before, they said that they just throw the cut off fat away and they could save me up as much as I wanted. But the next time I went, they enacted a new rule and would have to charge me for it. So I decided on the next cheapest option, getting two huge jugs of canola oil from Costco.

Here is what I wrote down 8 months ago, pardon the poor grammar, I just quickly took down these notes so I would remember what I did.

On 3/16/2020 I made my first batch of soap. I used 95% Canola oil and 5% Castor oil. Using Soapcalc.net, it calculated what I needed to use.

-I used a large Pyrex measuring cup to measure out 475g of canola oil.

-In a disposable plastic cup I measured out 25g of castor oil.

-In another large Pyrex measuring cup I measured out 190g of distilled water.

-In another disposable plastic cup I measured out 62g of Lye.

I put on safety goggles, gloves, and long sleeve shirt, and pants then went outside (very important!) I put the water in one 3 gallon bucket. ALWAYS PUT THE WATER IN FIRST! Then I poured in the lye. I used a bamboo kebab skewer to stir the lye until it was clear. The water and lye mixture gave off some really nasty fumes and the water rose to around 130 degrees.

Back inside, I took the Pyrex of canola oil and put it in the microwave for 2 minutes to bring it up to 130 degrees to match the same temperature as the lye water. I then poured both kinds of oil in the other 3 gallon gray bucket. I then poured the lye mixture into the oil mixture and used an electric mixer to mix for probably 2-3 minutes until it was very creamy looking and 100% mixed.

I then poured the mixture it into some molds.

The above batch filled up the pink silicone mold and it had enough left for ½ of a disposable plastic cup.

I wanted to make another batch so I doubled the above recipe. This was able to fill both of the cardboard molds.

This probably was a mistake to use a DIY cardboard mold. I first made the cardboard boxes and lined them with freezer paper. When I poured in the soap mix it started to seep through the cracks of the freezer paper and through the cardboard onto the table. I hurried and covered the outside of the cardboard molds with plastic wrap and that seemed to hold it. If I am going to use a cardboard mold again, I will wrap the entire thing in plastic wrap before I then line the inside with freezer paper.

I left the soap molds in a dark cool cupboard covered with a cloth for over 3 weeks until they were solid enough to be cut. I cut them into pieces and stood them up to get as much airflow as possible. I then left them in a cupboard for 7 months to cure.

7 months later, can you guess how they turned out!?

HORRIBLE…

DO NOT USE CANOLA OIL! It is not a good smelling oil, and I couldn’t get over the smell. It just was not worth it. The first two lathers of the soap worked well, but then the soap gave off a slimy gooey feeling after that – yuck!

I do have a couple jars of beef and pork lard that I got for free this year. Lard is the original way to made soap and how people have been doing it for hundreds of years, so hopefully it will work this time.

I’ll report back when I make that lard soap.

-

Friend of the Pod - December 5, 2020

Hi Robert,

As you’ve discovered the hard way, soap recipes where polyunsaturated fats predominate make poor soaps. This is for two reasons:

- The soap produced is soft/mushy, has an unpleasant greasy feeling on the skin, and doesn’t lather well.

- Because all home made soaps are superfatted (formulated with excess oil that is not saponified), combined with the fact that polyunsaturated fats are the most prone to oxidation, over time the excess fats in these soaps will go rancid, making them smell terrible.

Besides reading up on soap making, the best suggestion I can give you is that when you’re formulating a recipe on soapcalc.net you should shoot for an overall INS value of about 160. By doing so, you more or less guarantee you’ll get a good balance of saturated/monounsaturated/polyunsaturated fats. Higher is OK, though the higher you go the “harsher” the soap will be, but you don’t want to go too much lower. By way of illustration, your 95% canola/5% castor recipe gives an INS of 58, which is NOT good.

When you read #2 above, you may be tempted to change the superfatting percentage on your recipe to zero. Do not do this. The SAP values used to calculate the lye required for a recipe are based on “typical” values for a fat, but the actual SAP values for the particular fats we have on hand are almost certain to vary somewhat. By superfatting we guard against the case where the actual SAP values of our fats are lower than what is typical, which would otherwise result in a soap containing excess (unreacted) lye, which is undesirable for obvious reasons. In a well-formulated recipe, the unsaponified fats that remain in the finished soap will almost never be a problem. The worst that usually happens is that over an extended period of time the bars may develop what is commonly known as the Dreaded Orange Spots (DOS), a sign that the some of the excess fat has oxidized.

I hope this helps!

-

Friend of the Pod - December 5, 2020

A good online resource for soap makers is Miller’s Homemade Soap Pages

-

Robert LarsonContributor - December 6, 2020

Wow! Thank you so much for the incredible advice. You seem to know a lot about soap making.

You pointed out exactly all of the issues with my failed attempt. It was incredibly mushy, and I do believe it had oxidized because I saw orange spots on it and it smelt rancid and nasty too.

I’m going to try and make some beef/pig lard soap here probably in January or February, so hopefully I can run my recipe by you before I start.

-

Friend of the Pod - December 18, 2020

Hi Robert,

You’re welcome! And I would be more than happy to look at a recipe for you. That said, it’s honestly hard to go wrong if your recipe comes out with an INS near 160. BTW, I’ve used lard many times in recipes, and it makes nice soap. I’m sure tallow would too, I’ve just never used it because lard is cheap, and they sell it at my grocery store. 🙂

Anyway, now that coconut oil is available in most grocery stores, I’d suggest using at least a little of it in your formulations. It’s great for boosting INS, and helps soaps lather well. Palm oil is good too, if you can find it.

One more thing… Once you’ve cut a fresh batch of soap into bars, there’s no benefit to curing it for more than a month or so.

Happy soaping!

-Chris

-

Robert LarsonContributor - December 20, 2020

Thank you Chris. That is good that I don’t need to let it cure for more than a month. I thought that the 6 months that I previously waited was quite a long time.

-

-

LBV - December 27, 2020

I make my own soap, mainly because so many companies use palm oil and I don’t like that. My basic recipe is 40% olive oil, 30% beef tallow, 20% coconut and 10% castor oil with sodium hydroxide. I work with a 5% superfat (the amount of fat left in the bar after the mixture has saponified). I also add 20% sea salt (not iodised) calculated from the weight of water. The salt gets dissolved in the water before you add the lye. The advantage of the salt is that it makes a very hard bar, so it does not disintegrate in the soap dish. The downside is that you either need to use individualised moulds or work very quickly and cut the bar as soon as it solidifies. I use the calculator at soapcalc to work out the weights required.

The recipe above gives a hard white soap that does not strip my hands, produces a nice lather and can also pass for a shaving soap as well.

For a cleaning bar (laundry) I use a 100% coconut bar with a 0% superfat. I also add 20% salt to the water for hardness. This bar is not good for handfasting due to the lack of superfatting.

-

Robert LarsonContributor - December 28, 2020

That is very interesting that adding salt would change the hardness. I like that idea though! Does adding salt or not make you have to tweak the oil/water amounts if you add? Or is adding salt not something that affects the rest of the recipe?

Would sea salt vs table salt make a difference in the soap? I have a ton of very cheap table salt.

-

LBV - December 28, 2020

Before I started making soap I did some research. The one thing I noticed was that adding salt makes the bar set hard and fast, so there was the need to work fast. If using a loaf tin as a mould, you don’t leave it in long as it would set too hard to cut. You should be able to make the soap without the salt, the bar would probably lather more.

I wouldn’t think that adding table salt would make a difference, as long as it is not iodised. There are two ways to add salt – to the water which is dissolved, or to the soap itself just before moulding. The latter gives a bar that is exfoliating.

Using salt also effects the lathering ability of the soap. Coconut, is almost always used in bars that have salt as they can lather in salt. The problem with using coconut oil is that it can be very harsh on the skin due to the high levels of lauric acid which can be very drying. If you are making a 100% coconut bar you need a high level if superfatting – I read 20%.

My recipe has 50:50 hard fats:soft fats, so it should give a reasonably hard bar, even without the salt. The stearic acid in the tallow gives a hard bar and stable lather. The oleic acid from tallow and olive oil gives a moisturising and conditioning effect, while the risinoelic acid draws moisture and gives a stable lather.

-

Robert LarsonContributor - December 29, 2020

Great advice. Thank you!

-

-

Robert LarsonContributor - November 23, 2021

I have a large jar of beef tallow and also many jars of pork lard that I am wanting to turn into soap. They are very pure and there is no gristle or other contaminants in it.

My main hold up is that I am worried that the soap will have a beefy or porky smell to it after it’s done curing. I could use essential oils to mask the smell, but I don’t want beefy lavender soap either.

Has anyone made soap with tallow or lard and did it smell?

-

LBV - November 23, 2021

I haven’t noticed any unpleasant odour from my soaps, but adding a scent you like is always good. Be aware that if you are doing cold process, essential oils scent may not always last. Some oils also make the soap cure faster as well

-

Robert LarsonContributor - November 23, 2021

Thanks for sharing the tip about essential oils. I’ll stay clear of them then if they won’t be lasting anyways.

Have you tried making beef tallow or pork lard soap before?

-

LBV - November 23, 2021

It is easier to add essential oils to hot process or liquid soap, cold process needs to be cured over 3 weeks so they can fade, especially high notes.

I do use tallow in my soaps but in combination with other oils. Tallow should make a good soap as it is a solid fat and high in oleic acid. My recipe is above in earlier comments.

-

-

GB - November 28, 2021

Hi Conrad,

I’ve been making my own soap for a few years now and I won’t use anything other than homemade soap if I can help it.

My pet recipe uses 65% olive oil, 25% coconut oil and 10% Castor oil. I add sodium lactate for hardness. Adding salt like LBV does has the same effect.

I think if you can make a cake (even from a packet), you can make soap. My equipment for making soap is cheap, but dedicated*, cooking supplies and I shape my soap in silicon moulds from the local discount store. I thought the whole process very complicated, then I saw this video on YouTube. I love Marsha!

*Note, whatever equipment you decide to use for making soap, only use it for making soap, even though it becomes self cleaning after all the lye is taken up. I made mini meatloafs once using one of my soap moulds… Suffice to say, learn from my fail! 🙂

-

Robert LarsonContributor - January 26, 2022

-

- Shot Show 2026 recap - 1 week ago

- News for the Week 2026-1-12 - 3 weeks ago

- News for the Week 2026-01-05 - 4 weeks ago

- News for the Week 2025-12-29 - 1 month ago

- News for the Week 2025-12-22 - 1 month ago

This forum is heavily moderated to keep things valuable to as many people as possible. Full community policies are here. The basics:

- 1. Be nice to each other.

- 2. Stay focused on prepping.

- 3. Avoid politics, religion, and other arguments.

- 4. No unfounded conspiracies, fake news, etc.

- 5. Debate ideas, not people.