I recently asked if you were seeing increasing supply chain weirdness. The responses were interesting: smaller package sizes, fewer choices, and odd shortages. I decided to look into some of the more notable shortages from 2020, like PPE, disinfectants, and ammunition, to see if things have improved at all. I also discovered ongoing and upcoming price increases you should be aware of.

Important bits:

- In many cases, shortages and high prices are caused by lack of packaging, shortages of raw materials, overwhelming demand, or sometimes simple gouging.

- PPE supplies are better than they were a year ago, but producers are struggling.

- Food prices are rising and are expected to continue rising.

- Garden seed shipments are delayed, but largely due to the overwhelming number of orders, not due to a shortage of seeds.

- Building materials are reaching record-high prices just before the spring building season.

- Fuel prices are also going up, in part due to cold weather and also because of optimism over the COVID vaccine.

- Ammunition remains hard to buy, even for police departments. It might pay to buy firearms that use less-popular calibers.

- The microchips and other components needed for things like computers and cars are in short supply, causing a backlog across a wide range of products.

PPE and medical supplies

Personal protective equipment like masks and gloves was one of the first things to see shortages at the start of the pandemic, and while things are much better than a year ago, the supply chain is still under intense strain.

The Association for Professionals in Infection Control and Epidemiology ran a survey last fall in which 73% of respondents said they were required to reuse respirators. Additionally, healthcare workers are also dealing with millions of counterfeit N95 respirators on the market.

Gloves are also another hot item, with demand increasing 40% since COVID-19 vaccinations began. It takes about 35 days for medical groups to receive gloves.

Part of the problem is a shortage of raw materials, said Fisher Scientific in a message to customers in November. An American nitrile glove factory operated by Japan’s Showa Group is promising to triple its production capacity by next year, including a deal with an unspecified American chemical company to produce more nitrile.

The vaccines have also driven up demand for dry ice. Demand for dry ice in the United States has risen 1,138% year over year, and that demand is expected to continue rising. There are also issues sourcing enough steel, silicone, and borosilicate glass necessary to administer vaccines.

President Biden has signed an executive order using the Defense Production Act to mandate American manufacturers to make, among other things, more masks, gloves, and gowns, but that’s no guarantee that manufacturers will have the raw materials or the capacity to do so.

More: Have an Instant Pot? DHS says you can use it to decontaminate an N95

Disinfectants

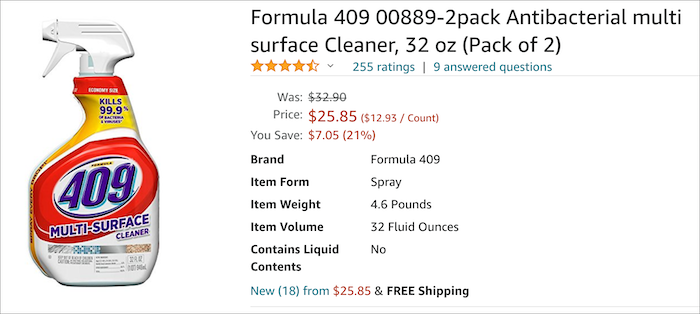

Another product category hit hard by the pandemic is cleaners and disinfectants. Things are slightly better a year later — you can sometimes buy things like disinfectant wipes in small quantities — but still pretty bad. I recently looked up some cleaner prices for our sleeping pad guide, and I was astonished to find Formula 409 at over $10 a bottle everywhere I looked.

But while manufacturers have boosted production and simplified product lines to make production more efficient, the demand is astronomical. The Clorox Company aims to double the production of disinfectant wipes by the end of 2021.

Here’s a tip: while Lysol and similar disinfectants are hard to find and overpriced, natural cleaners based on thymol are much more readily available, and thymol is effective against the SARS-CoV-2 virus.

More: Review: Force of Nature’s DIY at-home disinfectant

Food prices

We’re thankfully not experiencing food shortages, but prices are going up. The United Nations food price index has now hit its highest point in 6.5 years. In particular, cereals, sugars, and vegetable oils are jumping up in price.

Grain prices are something to keep a close eye on because that means higher prices for livestock grain. For example, the price of chicken wings has jumped from $70 for 40 pounds last year to $120 today. Anecdotally, my local milk supplier is raising milk prices because of the rising cost of feed.

Countries are hoarding food. China is building a stockpile, Argentina has ceased maize exports until the end of February, and Russia is taxing wheat, barley, and maize exports. The World Bank has warned that rising food prices have caused an epidemic of hunger throughout the world.

With the state of the food supply, more and more people are looking into gardening, which is causing problems of its own.

More: Gardening during COVID: feeding a family is a bigger challenge than you’d think

Seeds

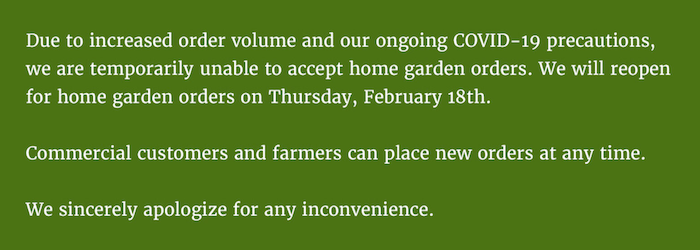

Normally, January and February are the best times to get a jump start on ordering seeds. However, many of the popular online seed stores are struggling to keep up with demand. Johnny’s Select Seeds had to temporarily shut down orders from home gardeners entirely because they don’t have the resources to ship all the orders.

Baker Creek, another popular seed vendor, hasn’t shut down orders but cautions that shipments could take 30 days or more. White Harvest Seed Company is advertising delays of 10 days. Southern Exposure Seed Exchange is accepting orders but is having to shut down intermittently to catch up.

What I have heard in private Facebook groups, and some of these public statements seem to support, is that there isn’t a seed shortage, but rather a shortage of packing materials. I heard from Baker Creek, who said:

Yes, we have run out of pre-printed packets on some of our varieties, and have had to resort to generic packets, which don’t have detailed information and photos of the variety they contain.

Getting sufficient seed packaged to meet the demand has also been problematic as order volume has remained unprecedentedly high. Social-distancing restrictions have aggravated the problem because we can’t run a full crew in some of our work areas.

Paper and packaging materials

A common thread in many supply chain issues is that there may be plenty of the base product, but nothing to package it in. Tony Smurfit of Smurfit Kappa has warned of rising costs of raw materials for paper-based packaging due to a combination of skyrocketing home deliveries and a sharp reduction in recycling. More paper is used and less is being reclaimed, which is wreaking havoc on the supply chain. That’s caused the price of corrugated containers to double.

It’ll also soon cost more to pack your dry foods in mylar, as DuPont has announced that starting in March 2021, it will be increasing the prices of Mylar and Melinex by at least 10 cents per pound.

Lumber and building materials

The price of building materials is through the roof. I recently had electricity connected to my shop building, and I paid about $1,000 over the original estimate, largely due to the sky-high price and limited availability of schedule 40 conduit.

It’s a bad time for any construction project because prices are at historical highs. Softwood lumber prices are 112% more expensive than a year ago and have jumped at least 10% in February alone. The culprits are increased demand for single-family homes and more renovation projects due to bored homeowners with big stimulus checks. Additionally, lumber is used for shipping pallets, and so the demand ties into skyrocketing shipments.

Overall demand dropped in 2019, so producers cut production for 2020, not anticipating the COVID-related building boom. The pandemic also caused lumber mills to shut down or slow production. Suppliers of other building materials have likewise been raising their prices to take advantage of the situation.

Even worse news: prices are soaring before we’ve even reached the spring building season.

Here’s a tip I heard from some homesteading friends: local sawmills might have much cheaper prices than your local lumber yard or home improvement store. It’s worth a call to potentially save some big money.

Fuel prices

You might have noticed rising prices at the pump, and when the price of fuel goes up, so does the price of everything else, because the price of transport also rises. AAA pins higher gas prices on the COVID-19 vaccines, which increases overall optimism about the pandemic, which causes more travel. Meanwhile, stay-at-home orders and refinery troubles are adding to higher prices.

Natural gas and propane prices are also rising due to the frigid winter. Natural gas is at two-year highs across the country and propane hasn’t been in this much demand since 2004.

More: How to store gas at home (and does gas go bad?)

Ammunition

This is not news to gun enthusiasts, but ammunition is scarce and expensive. Even if you’re aware of the shortage, it may be worse than you think. Some police departments are even having a hard time sourcing ammo.

What gives? Where’s the ammo? Outdoor Life interviewed Jason Vanderbrink, the president of ammunition for Vista Outdoor, who oversees top ammo brands like CCI, Federal, Speer, and Remington to get answers.

The simple answer again is unexpected demand. Sales were high during the Obama administration because gun owners thought gun control was imminent. They relaxed and stopped buying during the Trump administration, but sales exploded once COVID-19 hit the United States. Ammo manufacturers were caught with their pants down due to the so-called “Trump slump,” and it’s taken time to ramp production back up. Vista Outdoor is now producing more ammo than ever and it just isn’t enough.

On top of the high demand, there is a serious shortage of both primers and brass, both of which are essential to produce ammunition.

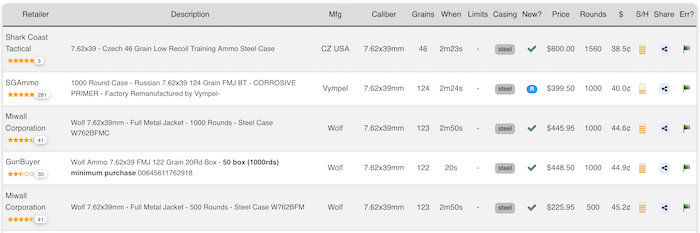

The conventional wisdom prior to COVID-19 was that it was wise to own firearms that work with the most popular calibers, like 9mm and 5.56x45mm NATO (the most common caliber in AR rifles), because that ammo would always be readily available. Unfortunately, that myth seems to be busted. On Ammoseek, 5.56x45mm NATO runs about 80 cents per round (it was around 30 cents pre-pandemic) and 9mm averages around 70 cents per round. However, if you shoot an AK-platform rifle that accepts 7.62x39mm, you’re looking at around 40 cents per round. Bear in mind those prices are for the absolute cheapest ammo and go up from there.

The preparedness lesson here is that shooting less-common calibers can be a benefit during ammo shortages.

More: Where and how to buy ammunition

Computer chips and electric car batteries

We’re also seeing supply constraints in the tech world, which could have a ripple effect on other industries. For example, if you’ve struggled to purchase a PlayStation 5 or an Xbox Series X, there’s a reason for that: a worldwide semiconductor shortage.

The chip shortage isn’t just affecting video game consoles and computers. Most automakers are struggling because they can’t get enough semiconductors to produce their increasingly computerized vehicles. General Motors is being forced to temporarily shut down factories until they can get enough chips to complete production vehicles. The only major automaker that doesn’t seem to be affected is Toyota, which had the wisdom to stockpile semiconductors before the supply crunch. (Toyota: the prepping automaker)

There are multiple reasons for the semiconductor shortage. Demand for PCs is at its highest in a decade, thanks to the millions suddenly working or schooling from home. Additionally, American companies have been increasingly shutting down their own chip factories and outsourcing them to specialized producers like Taiwan’s TSMC. The only problem is the handful of factories that now produce most of the world’s chips can only make so many. Finally, we’re also seeing lingering effects of Trump’s trade war with China, which has made it more difficult to source chips from there.

Electric vehicle makers are facing a second shortage: rising prices in the rare-earth elements necessary to make batteries. Demand for cobalt, an element used to prevent corrosion inside batteries, is especially high, with prices rising 20% since the start of the year. Tesla has been forced to postpone production of its semi-truck due to a lack of batteries.

You are reporting the comment """ by on